- Ajanta Compund, Mohan Nagar, Ghaziabad (U.P) India.

- msonsindustries@gmail.com

- +91-9717479797, +91-9811115754,+91-9818489797

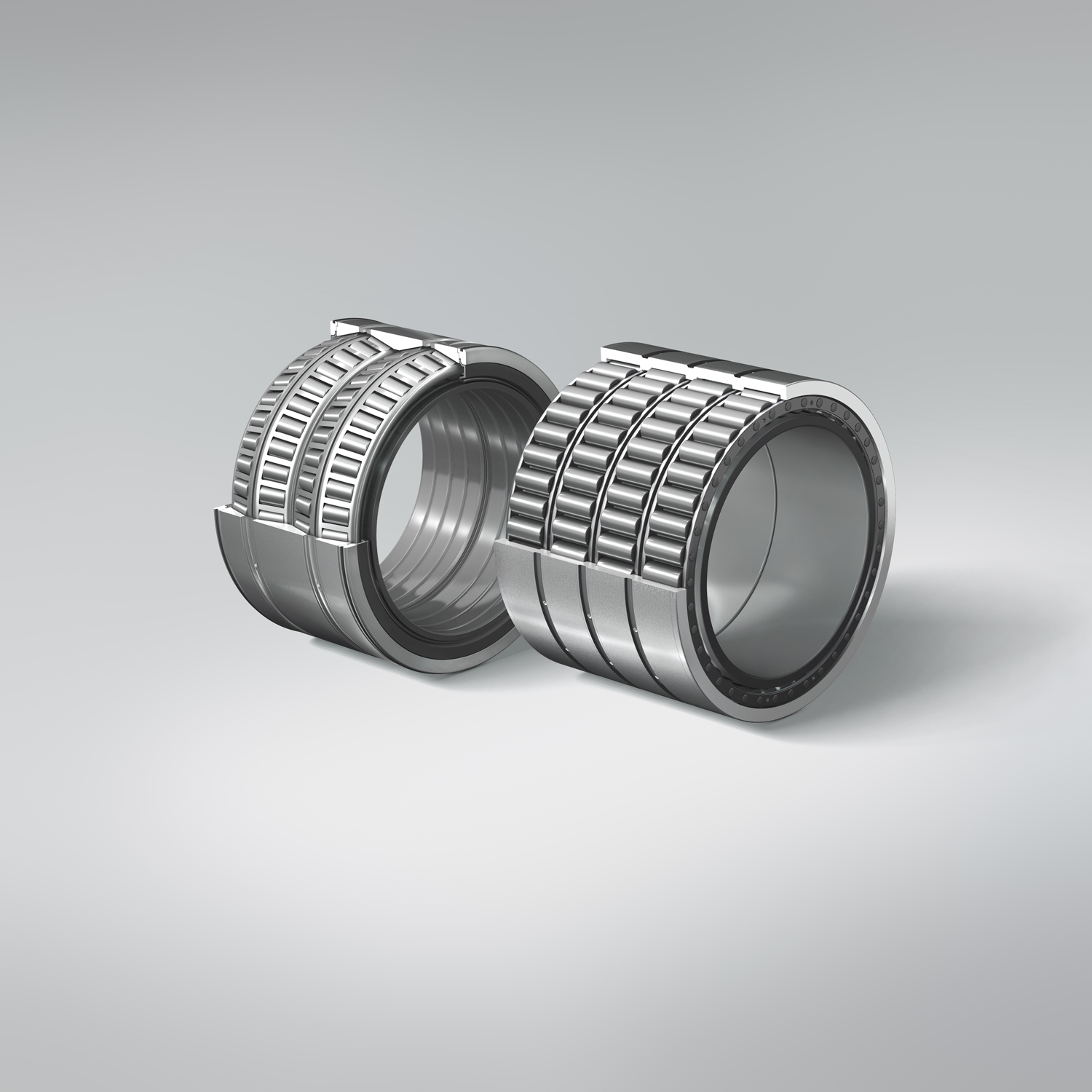

1. Due to tapered design, the bearing is able to carry a combination of significant radial & axial loads in particular in Cold Rolling Mills.

2. Depending upon the anticipated application loads, a higher radial capacity series or a higher axial capacity series is chosen. In almost all cases of 4 high or 6 high cold rolling mills, there is no need for an additional axial bearing in the assembly. This will contribute to a cost reduction in the overall assembly of back up rolls.

3. The most important advantage which a 4 Row Taper Roller Bearing has over Spherical roller bearing is that 4 Row taper roller assemblies are used mostly on roll neck application where high radial loads are carried and limited radial space is available.

This Type Of Bearing Is The Most Widely Used Bearings Amongst The Various Rolling Mill Bearings, In Cold Rolling Industry, The Main Characteristics Are:

1. The maximum dynamic load rating can be achieved with a limited mounting space.

2. They are applicable for high speed mills.

3. They permit more accurate limiting tolerances.

4. They can only accommodate radial load and as such for roll neck bearing application in cold rolling mills a thrust bearing is fitted on non driving side of roll neck, to accommodate for thrust loads.

These bearings are mainly used in machine assembly, where radial & axial loads are accommodated. However its use is limited to nominal loads & low speeds.

The bearings used in multi-roll cold strip rolling mill have a thinner wall thickness and they are mounted on back roll. They permit high radial load capacity & dimensional accuracy, however these bearings do not accommodate axial loads.

The bearings used in multi-roll cold strip rolling mill have a thinner wall thickness and they are mounted on back roll. They permit high radial load capacity & dimensional accuracy, however these bearings do not accommodate axial loads.

Angles are commonly used in the construction of buildings, equipments, vehicles, and other objects that we use in our everyday lives. They are very cheap and quite reliable for use as supporting structures in construction. Angles are steel structures with L cross-section in which the length of the legs could either be equal or unequal and the angle between the legs is 90 degrees.

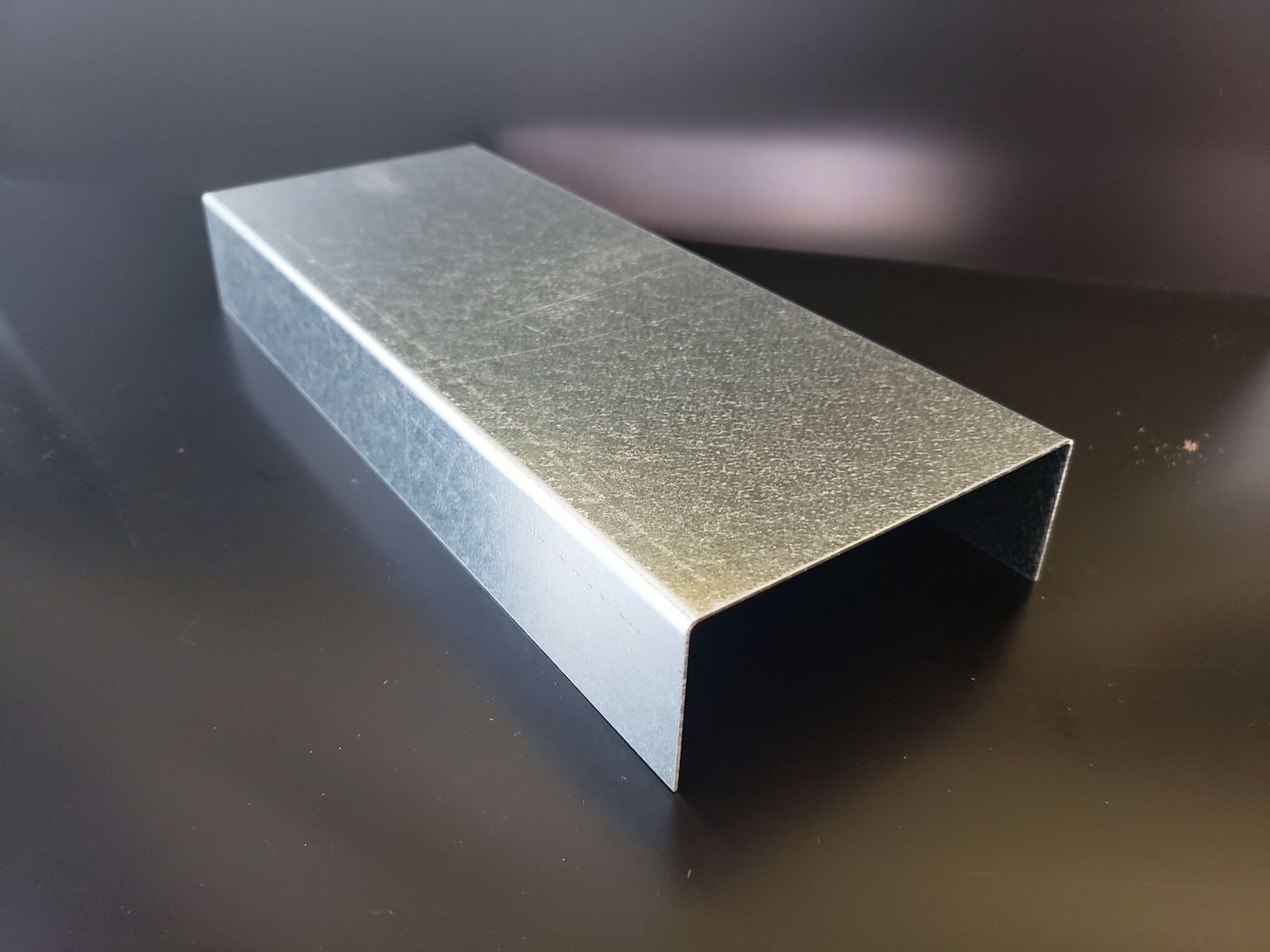

A channel is a hot-rolled mild steel structure that is C-shaped. The structure has a long vertical web and two flanges. Channels can be used both in indoor and outdoor applications. Steel channels are much lighter and more flexible than other structures but it usually experience twisting under certain loading types.

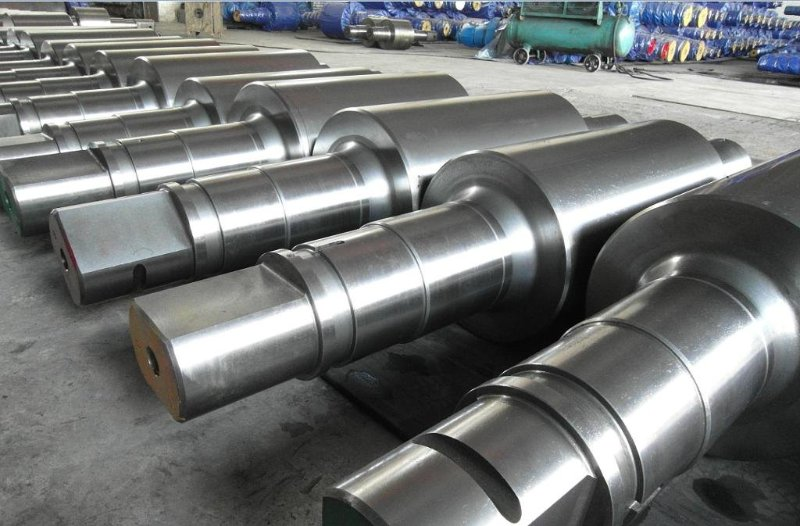

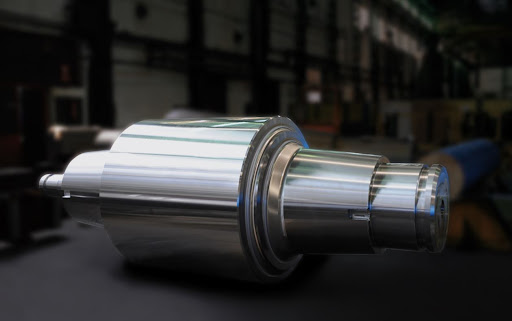

Forge steel roll provides a mill roller solution for rolling mill. It is one of the most wear parts during the rolling process. It is mainly made of forged steel. It is forged in hydraulic presses for high toughness and pureness, widely used in cold rolling mill, steckel mills and continuous hot strip mills. As different rolling mills have specific requirements and various rolling conditions, different alloy elements can be added into the steel for higher performance of the roll. The roll covers forged steel work roll or intermediate roll, forged steel back up roll.

Hot rolling is a metalworking process that involves heating steel to temperatures above its recrystallization point, usually over 1000° F, and passing it through rolling mills machinery. This process makes the steel more malleable, which allows it to be shaped and formed into different forms and thicknesses. The grains deform during processing, then recrystallize, which maintains an equiaxed microstructure and prevents the metal from work hardening.