- Ajanta Compund, Mohan Nagar, Ghaziabad (U.P) India.

- msonsindustries@gmail.com

- +91-9717479797, +91-9811115754,+91-9818489797

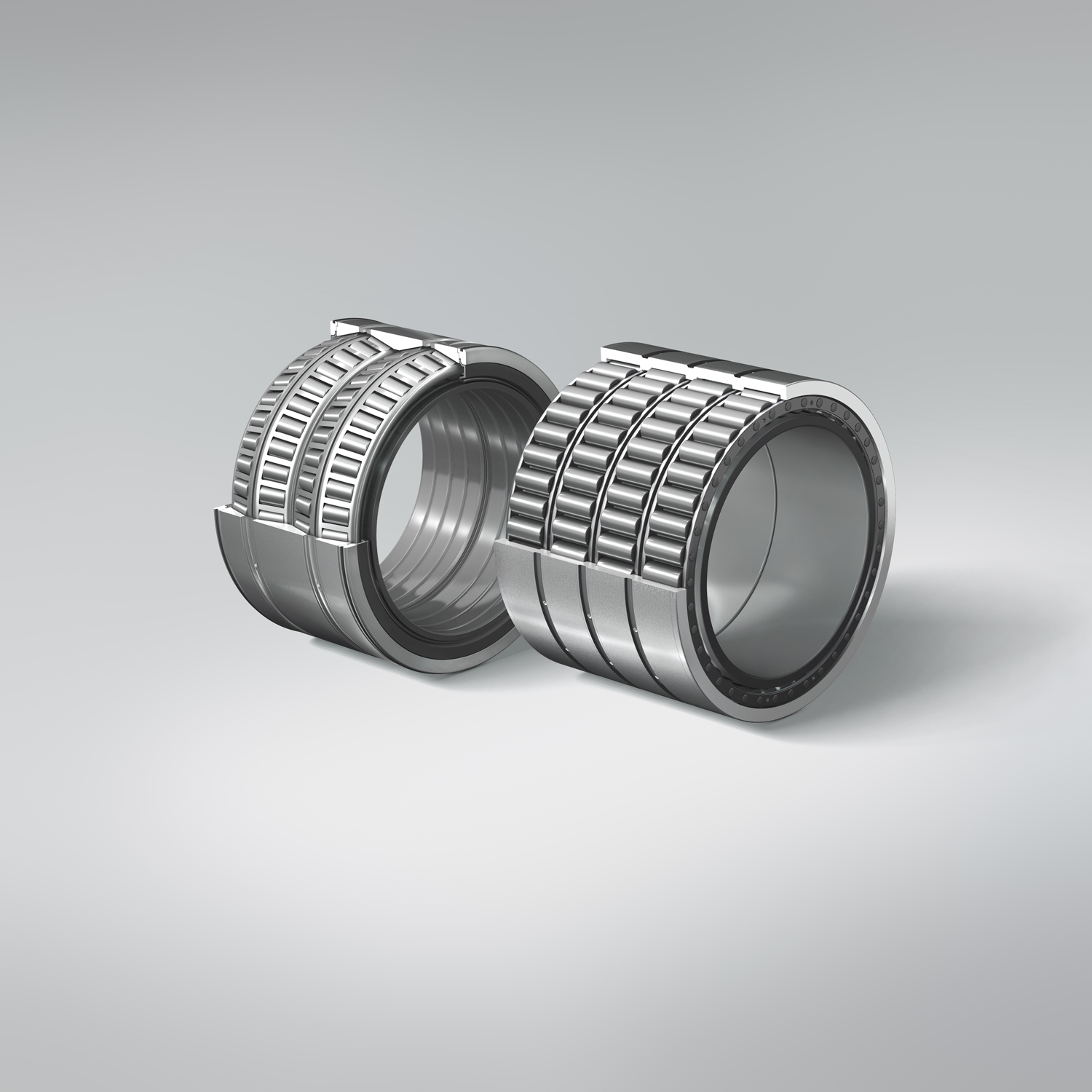

1. Due to tapered design, the bearing is able to carry a combination of significant radial & axial loads in particular in Cold Rolling Mills.

2. Depending upon the anticipated application loads, a higher radial capacity series or a higher axial capacity series is chosen. In almost all cases of 4 high or 6 high cold rolling mills, there is no need for an additional axial bearing in the assembly. This will contribute to a cost reduction in the overall assembly of back up rolls.

3. The most important advantage which a 4 Row Taper Roller Bearing has over Spherical roller bearing is that 4 Row taper roller assemblies are used mostly on roll neck application where high radial loads are carried and limited radial space is available.

This Type Of Bearing Is The Most Widely Used Bearings Amongst The Various Rolling Mill Bearings, In Cold Rolling Industry, The Main Characteristics Are:

1. The maximum dynamic load rating can be achieved with a limited mounting space.

2. They are applicable for high speed mills.

3. They permit more accurate limiting tolerances.

4. They can only accommodate radial load and as such for roll neck bearing application in cold rolling mills a thrust bearing is fitted on non driving side of roll neck, to accommodate for thrust loads.

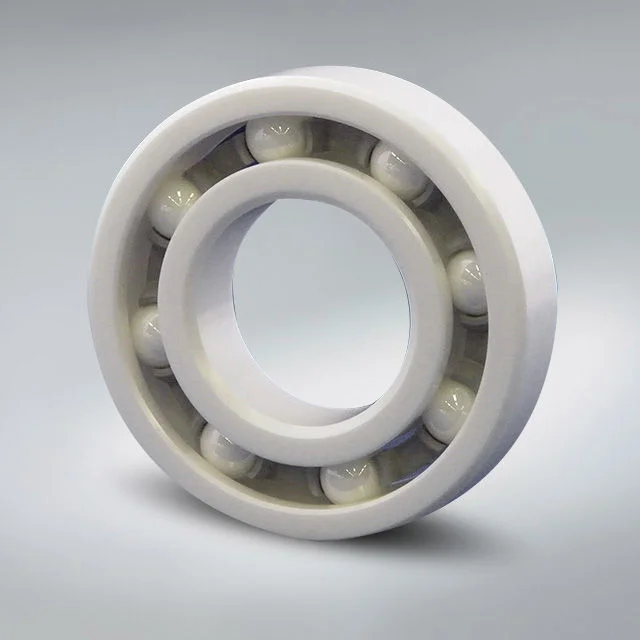

Ball bearings are the most-well known type of bearing. They typically offer lower load capacity but can support high speeds and have been proven in countless applications.

NSK manufactures a full range of deep groove ball bearings (DGBBs). These versatile bearings are the most common type and serve a wide variety of industries.

Besides radial loads, DGBBs can take axial loads in both directions and offer low frictional torque and high-speed components ideal for applications requiring low noise and vibration.

NSK’s comprehensive range of angular contact ball bearings is designed to meet the ever-evolving requirements of equipment manufacturers.

Angular contact ball bearings feature a contact angle that sustains significant axial loads in one direction at the same time as radial loads.

Since an axial component is generated when radial load is applied, these bearings are typically used in pairs or multi-bearing sets.

Self-aligning ball bearings are recommended for applications where aligning the shaft and housing is difficult or where the shaft may bend, such as transmission shafts. The outer ring has a spherical raceway and its center of curvature coincides with that of the bearing, allowing the axis of the inner ring, balls, and cage to rotate freely around the bearing center. Pressed steel cages are typically used for this type.

Since they have a small contact angle, self-aligning ball bearings have low axial load capacity. Permissible dynamic misalignment is approximately 0.07 to 0.12 radian (4 to 7 degrees) under normal loads; however, such angles may not be allowable depending on the surrounding structure.

Thrust ball bearings are designed to take axial (thrust) loads at high speeds, but they cannot handle any radial loads. These bearings feature bearing washers with raceway grooves in which the balls move.

Thrust ball bearings are classified into “flat seat” and “aligning seat” types, based on the shape of the housing washer (outer ring seat), and as single-direction or double-direction. Spherical and aligning seat washers help to provide tolerance for mounting errors.

Extremely thin-section ball bearings contribute to equipment downsizing, lighter weight, and low torque in robots, construction equipment, and industrial machinery.

With lower frictional torque and less torque variation, N Series bearings improve torque transmission and provide smooth rotation. These high-precision bearings also support high speeds.

Roller bearings are typically suited to high loads and low speeds. Rollers come in a variety of sizes and shapes to provide different operating characteristics.

Cylindrical roller bearings (CRBs) have a simple structure of cylindrical rollers in linear contact with the raceways. They offer high load capacity under primarily radial loads. Low friction between the rollers and ring ribs makes these bearings suited for high speed rotation.

Single-row bearings are designated as NU, NJ, NUP, N, or NF, while double-row bearings are designated as NNU or NN, depending on if side ribs are used. All types allow the inner and outer rings to be separated.

Some CRBs used as free-end bearings have no ribs so that the rings can move axially relative to each other. When the inner or outer ring has ribs on both sides and the other ring has a rib on one side, these bearings can take some axial load in one direction.

Double-row cylindrical roller bearings have high radial rigidity and are used primarily for the main shafts of precision machine tools. Cages are typically made of pressed steel or machined brass, but molded polyamide resin cages are used for some models.

NSK offers a variety of CRB types to suit your needs.

Tapered roller bearings are designed so that the imagined conical apices formed by the raceways of the inner and outer rings and the rollers all converge at one point on the bearing axis. The trapezoidal tapered rollers used as the rolling elements are guided by a large rib on the inner ring.

TRBs can take radial loads and axial loads in one direction. When load is applied, the axial component generated inside the bearing generally requires the use of two opposed bearings (similar to angular contact ball bearings) or double-row bearings. Spacers are used to adjust the inner and outer rings in the axial direction to achieve the proper internal clearance. Since they are separable, the inner ring (cone) assemblies and outer rings (cups) can be mounted independently.

The HR Series increases both the size and number of rollers for even higher load capacity.

Tapered roller bearings are divided by their contact angle into normal-, medium-, and steep-angle types. In addition to double-row types, four-row tapered roller bearings are also available. Pressed cages are generally used, though large bearings may utilize pin-type cages.

Spherical roller bearings are available in EA, C, CD, and CA types designed for high load capacity. Types EA, C, and CD have pressed steel cages, while CA uses machined brass cages. All EA types are high-performance standard NSKHPS Series bearings.

NSKHPS Series bearings have especially high load capacity, high limiting speeds, and excellent performance at temperatures up to 200°C.

Designations suffixed with “E4” have an oil groove and holes on the outer ring. Since the depth of the oil groove in these bearings is limited, we recommend using an oil groove in the housing bore as well.

Available with cylindrical, tapered, and spherical rollers, thrust roller bearings sustain only axial loads. NSK’s thrust roller bearings are suitable for heavy loads and offer high axial rigidity. Machined brass cages are used as standard.

Thrust tapered roller bearings come in two types: the TT type, which has a flange on the housing washer (outer ring), and the TTF type, which does not. The TT type is suitable when it can be securely fixed in the radial direction, while the TTF type tolerates slight misalignment that occurs between the shaft and housing during operation.

Thrust spherical roller bearings contain convex rollers that make them self-aligning and unaffected by mounting error and shaft deflection. The E-type offers a high load capacity design with a pressed steel cage.

Needle roller bearings (sometimes called “needle bearings”) use long and narrow cylindrical rollers that sometimes exceed JIS/ISO size ranges. They are categorized as thrust or radial bearings based on which load direction they support. Radial types include drawn-cup and solid types, as well as application-specific track rollers (cam and roller followers). Thrust needle and thrust roller bearings respond to axial load needs.

NSK ball bearing units combine a bearing, housing, and sealing components into a standardized form used in the key parts of equipment. They are versatile and easy to use.

Using a ball bearing unit simplifies the surrounding structure and makes mounting and maintenance more efficient. As they provide the proper alignment, bearing units help prevent moment loads caused by mounting error. Bearing units can also be easily mounted on the machine base or side walls so they can be used in all kinds of places, including frame structures.

With their impressive features, applications for bearing units are expanding daily, and NSK’s wide range of ball bearing units continues to meet performance needs across operating environments.

Super precision bearings offer a step up in performance with specialized materials and manufacturing accuracy. These improvements provide various benefits, including longer life, higher speeds, improved equipment precision, and more.

NSK offers a wide lineup of super precision angular contact ball bearings to provide optimal specifications for your application.

Our bearings provide the perfect solution for equipment requiring high running accuracy or high rotational speed, such as the main spindles of machine tools.

Lineup Highlights

NSK super precision cylindrical roller bearings are designed specifically to handle large radial loads in high-speed spindle applications that require high running accuracy.

Lineup Highlights

High-precision angular contact thrust ball bearings for precision ball screws are designed for a wide variety of applications with a range of high rigidity and high load capacity series available.

Lineup Highlights

NSK provides angular contact ball bearings specially designed for machine tool swivel heads. These bearings match the high-precision processing needed in multi-spindle configurations. In particular, our ROBUSTSLIM high-accuracy low-profile angular contact ball bearings offer high rigidity with low torque.

Features

Super precision bearings offer a step up in performance with specialized materials and manufacturing accuracy. These improvements provide various benefits, including longer life, higher speeds, improved equipment precision, and more.

Sanitary bearings use NSF H1* food-grade lubricant to provide an extra level of safety in applications such as food processing machinery.

*NSF International: U.S. third party accreditation organization that is internationally recognized in the field of public safety and health. The H1 certification indicates the grease is suited for incidental food contact with a high level of safety.

Highly corrosion-resistant bearings are used in tough environments where water, weak/strong acids, alkali, or reactive gases are present.

Our stainless steel, hybrid, Molded-Oil™, and coated bearings stand up to moist and wet environments while our ceramic and ESZ bearings withstand weak acid and alkaline environments. For environments where strong acids and reactive gases are present, we offer ceramic bearings and Aqua-Bearings™.

Vacuum bearings are a standard line in our SPACEA Series for special environments.

Further specialized SPACEA bearings are available for corrosive, cleanroom, and high-temperature applications.

Cleanroom bearings aim for zero particle emissions.

By applying NSK’s unique technologies, our range of offerings excel across environments at atmospheric pressure, in vacuum, and with high temperatures.

High temperature bearings use specialized lubricants to stand up to intense heat.

Grease-packed bearings are pre-filled with fluorine grease for high temperatures, while YS and SJ bearings use molybdenum disulfide (MoS2) solid lubricant to withstand temperatures up to 350°C and 400°C respectively.

Nonmagnetic bearings offer higher rigidity and greater resistance to corrosion than conventional stainless steel or beryllium-copper alloys.

NSK’s dust-resistant bearings use a special material with a polyolefin resin that has an affinity for lubrication oil. This unique material is sealed in the bearing and provides continuous lubrication in tough environments with dust, wood chips, or other contaminants.

Stainless steel options are available for environments where bearings are also exposed to water.